Explore Battery Assembly Machines: Explanation, Knowledge, and Practical Insights

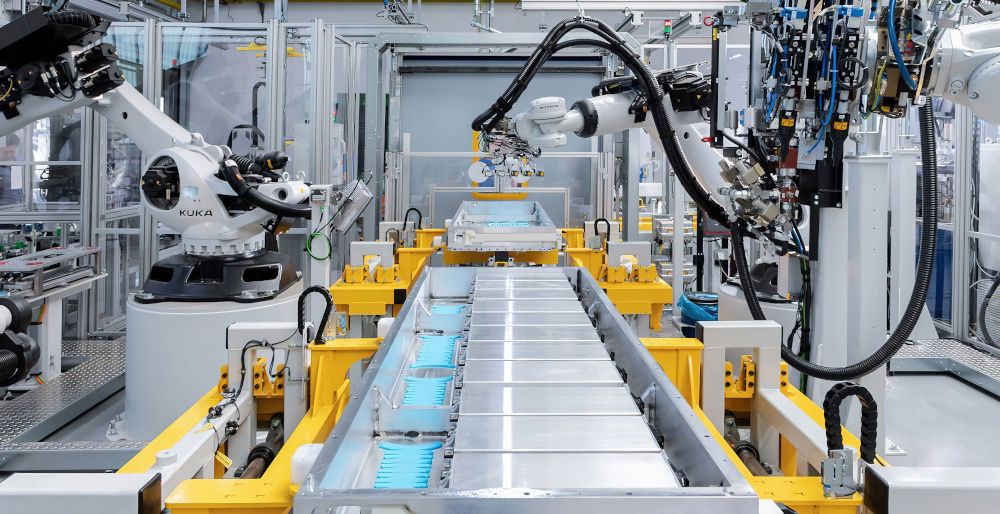

Battery assembly machines are industrial systems designed to automate and control the step-by-step process of building batteries. These machines handle tasks such as electrode stacking, cell winding, electrolyte filling, sealing, testing, and labeling. Their core purpose is to produce batteries with consistent quality, safety, and performance while supporting large-scale manufacturing needs.

As batteries became central to modern technology, manual assembly alone was no longer sufficient. The demand for higher energy density, tighter tolerances, and safer production environments led manufacturers to adopt automated battery manufacturing equipment. Battery assembly machines now form the backbone of production lines for lithium-ion battery assembly, advanced energy storage systems, and next-generation cell formats used across industries.

As batteries became central to modern technology, manual assembly alone was no longer sufficient. The demand for higher energy density, tighter tolerances, and safer production environments led manufacturers to adopt automated battery manufacturing equipment. Battery assembly machines now form the backbone of production lines for lithium-ion battery assembly, advanced energy storage systems, and next-generation cell formats used across industries.

In simple terms, these machines exist to make battery production faster, more precise, and more reliable than human-only processes could achieve.

Importance: Why Battery Assembly Machines Matter Today

Battery assembly machines play a critical role in today’s technology-driven world. Batteries power electric mobility, consumer electronics, renewable energy storage, medical devices, and industrial equipment. Any variation in battery quality can affect safety, lifespan, and performance.

Key reasons these machines matter include:

-

Consistency and accuracy

Automated systems reduce human error and ensure uniform cell construction, which improves battery reliability. -

Safety in manufacturing

Batteries involve reactive materials. Machines limit direct human exposure to chemicals and high-energy components. -

Scalability of production

As demand grows, automated battery production lines support higher output without sacrificing precision. -

Efficiency and waste reduction

Controlled processes reduce material loss and improve yield rates.

Industries affected include electric mobility, electronics manufacturing, energy storage infrastructure, and industrial automation. For end users, the impact is indirect but significant: longer-lasting devices, safer products, and more dependable energy solutions.

Recent Updates: Key Developments and Industry Trends

Recent developments in battery assembly technology focus on precision, flexibility, and data integration. Over the past year, manufacturers have emphasized smarter machines that adapt to changing battery designs without major hardware changes.

Notable trends include:

-

Shift toward modular machine design

Modular battery assembly systems allow production lines to adjust quickly for different cell formats and chemistries. -

Increased use of machine vision systems

High-resolution cameras and sensors now inspect electrodes, welds, and seals in real time. -

Data-driven manufacturing

Integration with manufacturing execution systems enables real-time tracking of quality metrics and process stability. -

Improved dry-room compatibility

Equipment is increasingly optimized for low-humidity environments required for lithium-based cell assembly.

These updates reflect a broader movement toward smart manufacturing, where battery production equipment not only assembles cells but also generates data for quality control and predictive maintenance.

Laws or Policies: Regulatory Influence on Battery Assembly

Battery assembly machines are shaped by safety, environmental, and industrial regulations. In many countries, policies focus on safe handling of chemicals, workplace safety, and responsible manufacturing practices.

Common regulatory influences include:

-

Industrial safety standards

Rules governing machinery guarding, emergency stops, and operator protection affect machine design. -

Environmental compliance requirements

Regulations on waste handling and emissions encourage cleaner and more efficient battery manufacturing processes. -

Energy and sustainability programs

Government initiatives promoting energy storage and electric mobility indirectly drive demand for advanced battery production equipment. -

Quality and traceability guidelines

Standards require manufacturers to track production data, influencing the adoption of digitally connected assembly machines.

While regulations do not usually specify machine models, they strongly influence how battery assembly systems are engineered and operated.

Tools and Resources: Practical Support Around Battery Assembly Machines

A range of tools and resources support understanding and managing battery assembly processes. These resources help manufacturers, engineers, and planners evaluate production efficiency and quality.

Helpful resources include:

-

Battery production simulation software

Used to model assembly workflows and identify bottlenecks. -

Process monitoring dashboards

Visual tools that track output, defect rates, and equipment status. -

Technical standards documentation

Reference materials outlining accepted practices for battery manufacturing. -

Training modules and virtual labs

Educational platforms that explain battery assembly stages and machine operation principles. -

Quality control templates

Structured formats for recording inspection and testing data.

These tools complement battery assembly machines by improving decision-making and operational transparency.

How Battery Assembly Machines Work: A Practical Overview

Battery assembly machines operate in a sequence of tightly controlled steps. Each stage builds upon the previous one to form a complete and functional battery cell.

Typical stages include:

-

Electrode preparation and stacking

Layers of anode and cathode materials are aligned with separators. -

Cell forming and enclosure

The stacked or wound electrodes are placed into a casing. -

Electrolyte filling

A precise amount of electrolyte is injected under controlled conditions. -

Sealing and welding

The cell is closed to prevent leakage and contamination. -

Testing and inspection

Electrical and visual checks verify performance and safety.

The entire process is synchronized to maintain accuracy and repeatability, which are essential for large-scale battery manufacturing.

Table: Core Functions of Battery Assembly Machines

| Assembly Stage | Primary Function | Key Benefit |

|---|---|---|

| Electrode stacking | Aligns active materials | Uniform energy distribution |

| Electrolyte filling | Controls liquid volume | Stable chemical performance |

| Sealing and welding | Secures cell enclosure | Improved safety and durability |

| Testing and inspection | Verifies electrical behavior | Early defect detection |

FAQs: Common Questions About Battery Assembly Machines

What types of batteries use assembly machines?

Battery assembly machines are used for lithium-based cells, cylindrical cells, prismatic cells, and pouch cells across multiple applications.

Are these machines fully automated?

Many systems are highly automated, though some production lines combine automation with supervised manual steps for flexibility.

How do machines improve battery safety?

They maintain controlled environments, precise material handling, and consistent sealing, reducing the risk of defects.

Do battery assembly machines support different cell designs?

Modern systems are designed to adapt to multiple formats through adjustable tooling and software-driven controls.

Why is data tracking important in battery assembly?

Data helps identify quality trends, improve yield, and support traceability throughout the production process.

Conclusion: Understanding the Role of Battery Assembly Machines

Battery assembly machines are essential to modern manufacturing ecosystems. They enable precise, safe, and scalable production of batteries that power everyday technologies and advanced energy systems. Through automation, data integration, and compliance with safety standards, these machines help ensure that batteries meet growing performance expectations.

As battery technology continues to evolve, assembly machines will remain central to delivering reliable energy storage solutions. Understanding how they work and why they matter provides valuable insight into the foundation of today’s electrified world.