Guide to Stainless Steel Supplies for Builders, Makers & Engineers

Stainless steel supplies refer to the range of stainless steel materials available in different grades, shapes, and finishes for use in construction, manufacturing, engineering, and fabrication. These materials are valued for their corrosion resistance, strength, durability, and adaptability across varied environments.

Stainless steel exists as a material category to address limitations found in ordinary carbon steel, particularly corrosion, hygiene concerns, and long-term durability. For builders, makers, and engineers, stainless steel supplies provide reliable material options for structural components, machinery, tools, and precision applications where performance consistency is critical.

Understanding Stainless Steel Supplies and Why They Exist

Stainless steel is an alloy primarily made of iron, chromium, and varying amounts of other elements such as nickel, molybdenum, and carbon. The presence of chromium creates a passive oxide layer on the surface, which protects the material from rust and corrosion.

Stainless steel supplies exist to support applications where exposure to moisture, chemicals, heat, or mechanical stress is expected. Traditional steels may degrade under such conditions, whereas stainless steel maintains its structural and surface properties over extended periods.

Key reasons stainless steel supplies are used include:

-

Resistance to corrosion and oxidation

-

Long service life in demanding environments

-

Strength across a wide temperature range

-

Ease of fabrication and forming

-

Compatibility with hygienic and clean environments

These characteristics make stainless steel a foundational material in modern engineering and construction.

Why Stainless Steel Matters for Builders, Makers, and Engineers

Stainless steel is important today because infrastructure, manufacturing, and product design increasingly demand materials that balance performance, longevity, and reliability. Builders require materials that withstand environmental exposure, while makers and engineers need predictable mechanical and chemical behavior.

Stainless steel supplies matter because they support:

-

Structural stability in construction projects

-

Precision and consistency in engineered components

-

Corrosion resistance in outdoor and marine environments

-

Cleanability in food, medical, and laboratory settings

-

Reduced maintenance over long operational periods

Industries and disciplines that commonly rely on stainless steel include:

-

Building and infrastructure development

-

Mechanical and industrial engineering

-

Fabrication and metalworking

-

Automotive and transportation systems

-

Energy, chemical, and processing industries

For professionals working with metal, stainless steel provides a dependable balance between strength and durability.

Recent Trends and Updates in Stainless Steel Usage

Over the past year, stainless steel usage patterns have reflected changes in construction practices, manufacturing technologies, and material standards. In 2025, several trends influenced how stainless steel supplies are selected and applied.

Key developments include:

-

January 2025: Increased preference for corrosion-resistant grades in coastal and high-humidity projects

-

April 2025: Wider use of precision-finished stainless steel sheets for architectural applications

-

July 2025: Growing adoption of stainless steel in modular and prefabricated construction systems

-

October 2025: Improved traceability and material certification practices in industrial supply chains

Another notable trend is the emphasis on lifecycle performance. Engineers and builders increasingly evaluate stainless steel based on long-term durability rather than short-term material substitution.

Advances in forming and finishing technologies have also expanded design flexibility for makers and fabricators.

Standards, Regulations, and Material Specifications

Stainless steel supplies are governed by international and national standards that define composition, mechanical properties, and testing methods. These standards ensure consistency, safety, and interchangeability across projects.

Key areas of standardization include:

-

Material composition standards

Define allowable ranges of alloying elements such as chromium and nickel. -

Mechanical property standards

Specify tensile strength, yield strength, and elongation values. -

Dimensional and tolerance standards

Control thickness, diameter, and flatness of supplied materials. -

Surface finish classifications

Describe polished, brushed, and mill finishes.

In India and globally, stainless steel materials commonly align with standards issued by recognized standards organizations and engineering bodies. Compliance with these specifications helps engineers and builders ensure material reliability.

Common Grades of Stainless Steel

Stainless steel supplies are categorized into grades based on composition and performance characteristics.

| Stainless Steel Series | Common Grades | Key Characteristics |

|---|---|---|

| Austenitic | 304, 316 | High corrosion resistance, good formability |

| Ferritic | 430 | Moderate corrosion resistance, magnetic |

| Martensitic | 410 | High strength, moderate corrosion resistance |

| Duplex | 2205 | High strength, enhanced corrosion resistance |

| Precipitation hardening | 17-4 PH | High strength and toughness |

Each grade is selected based on environmental exposure, mechanical requirements, and fabrication methods.

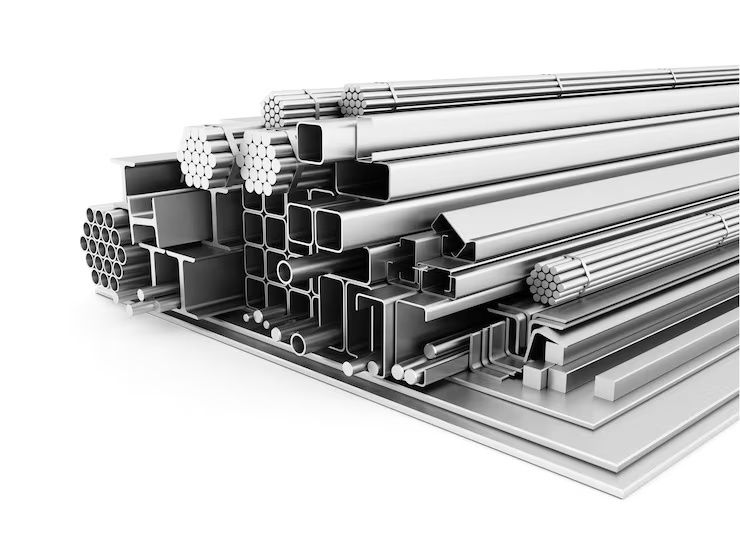

Forms of Stainless Steel Supplies

Stainless steel is available in multiple physical forms to support different applications.

-

Sheets and plates

Used in cladding, enclosures, tanks, and structural panels. -

Pipes and tubes

Common in fluid handling, structural frames, and heat exchangers. -

Bars and rods

Used for machining components, fasteners, and shafts. -

Angles, channels, and sections

Applied in structural frameworks and supports. -

Wire and mesh

Used in filtration, reinforcement, and specialized fabrication.

The availability of different forms allows builders and engineers to select materials suited to specific design needs.

Role of Stainless Steel in Construction and Engineering

Stainless steel plays multiple roles across construction and engineering projects.

For builders, it supports:

-

Structural elements exposed to weather

-

Architectural finishes requiring visual consistency

-

Reinforcement in specialized environments

For engineers and makers, it enables:

-

Precision-machined components

-

Equipment frames and housings

-

Mechanical assemblies exposed to stress and heat

Its predictable behavior during cutting, forming, welding, and machining makes stainless steel suitable for both large-scale construction and detailed fabrication work.

Tools and Resources for Working With Stainless Steel

Working with stainless steel effectively requires appropriate tools and reference materials.

Commonly used resources include:

-

Material reference tools

-

Stainless steel grade comparison charts

-

Mechanical property tables

-

-

Fabrication and processing tools

-

Cutting and forming guidelines

-

Welding procedure references

-

-

Testing and inspection resources

-

Surface finish measurement standards

-

Corrosion resistance testing methods

-

-

Standards and documentation

-

Material certification formats

-

Engineering specification documents

-

These resources help ensure accurate selection, processing, and verification of stainless steel materials.

Comparison: Stainless Steel vs Other Common Metals

| Property | Stainless Steel | Carbon Steel | Aluminum |

|---|---|---|---|

| Corrosion resistance | High | Low | Moderate |

| Strength | High | High | Moderate |

| Weight | Moderate | High | Low |

| Maintenance requirement | Low | Higher | Low |

| Temperature resistance | High | High | Moderate |

This comparison explains why stainless steel is often chosen where durability and corrosion resistance are critical.

Frequently Asked Questions

What makes stainless steel different from regular steel?

Stainless steel contains chromium, which forms a protective surface layer that resists corrosion.

Are all stainless steel grades corrosion resistant?

All grades offer some resistance, but performance varies depending on composition and environment.

Which stainless steel grade is commonly used in construction?

Austenitic grades such as 304 and 316 are commonly used due to their balance of strength and corrosion resistance.

Is stainless steel suitable for outdoor applications?

Yes. Many grades perform well outdoors, especially in urban and coastal environments.

Does stainless steel require surface protection?

In most cases, no additional coating is required, though surface finish selection is important.

Challenges in Selecting Stainless Steel Supplies

Professionals may face challenges such as:

-

Choosing the correct grade for specific environments

-

Balancing strength, formability, and corrosion resistance

-

Understanding surface finish requirements

-

Ensuring compatibility with fabrication methods

-

Interpreting material standards correctly

Addressing these challenges requires careful evaluation of application conditions and specifications.

Stainless Steel and Sustainability Considerations

Stainless steel supports sustainability goals due to its long service life and recyclability. Key sustainability aspects include:

-

Extended lifespan reducing material replacement

-

High recyclability without loss of properties

-

Resistance to corrosion minimizing protective treatments

-

Efficient material usage through precise engineering

These factors make stainless steel a long-term material choice for responsible construction and manufacturing.

Future Outlook for Stainless Steel Supplies

The future of stainless steel supplies is shaped by evolving construction methods and engineering demands. Expected developments include:

-

Increased use in modular and lightweight structures

-

Enhanced surface finishes for architectural design

-

Improved material traceability and certification

-

Continued focus on durability and lifecycle performance

These trends indicate sustained relevance for stainless steel across industries.

Conclusion

Stainless steel supplies form a critical foundation for builders, makers, and engineers working in construction, manufacturing, and design. The material exists to provide corrosion resistance, strength, and long-term reliability in environments where conventional metals may not perform adequately.

Recent trends emphasize durability, precision, and traceability, while standards and specifications guide consistent material usage. By understanding stainless steel grades, forms, and applications, professionals can make informed material choices that support structural integrity, performance, and sustainability in modern projects.